Read on to learn how How 3D modeling is changing the furniture industry.

Technology marches on, always moving forward, often at frightening speed. In many cases, it brings better products and opens new possibilities. One area where technology has been really transformative, is 3D Modeling.

What is 3d Modeling?

When creating new products, the traditional approach for years was to create a physical model, so that its proportions, looks, performance and so on could be assessed more readily. 3D modelling takes that idea and digitizes it.

It allows designers to create exact models of any new product, but in the digital world.

Because the models are accurate to the last detail, they represent the ultimate in design development, without the time and cost of producing endless prototypes.

How Does that Benefit the 3D Furniture Industry?

There are several benefits to this approach, some are general benefits to any design process including the furniture industry, some are very specific for furniture makers and customers.

Improved Product Development in 3D Modeling

The first benefit of 3D modeling is a faster, and less costly development process. Instead of building new models for each iteration, the digital model; can be changed quickly as needed while the design is in development.

Take More Chances

For designers, development costs mean that they must be conservative in their approach. If a designer takes a risk that later proves to be a problem for construction or simply is not received well, the sunk cost involved means disaster. However, with 3D modelling, there is significantly less penalty for designs that don’t quite work out.

This gives designers the scope to be more creative, freeing them to try new things. This is good for deign professionals, but for the furniture industry, it could see the birth of a new design revolution that captures the imagination of consumers the world over.

Improved Results

One of the main challenges with any furniture design is materials.

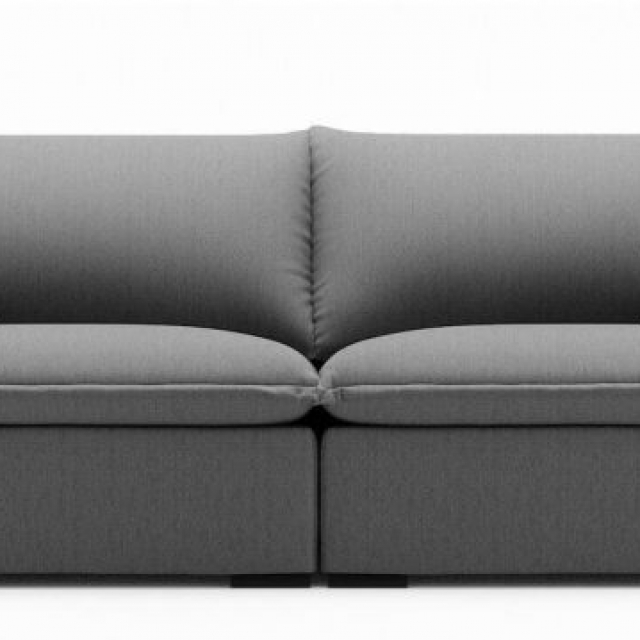

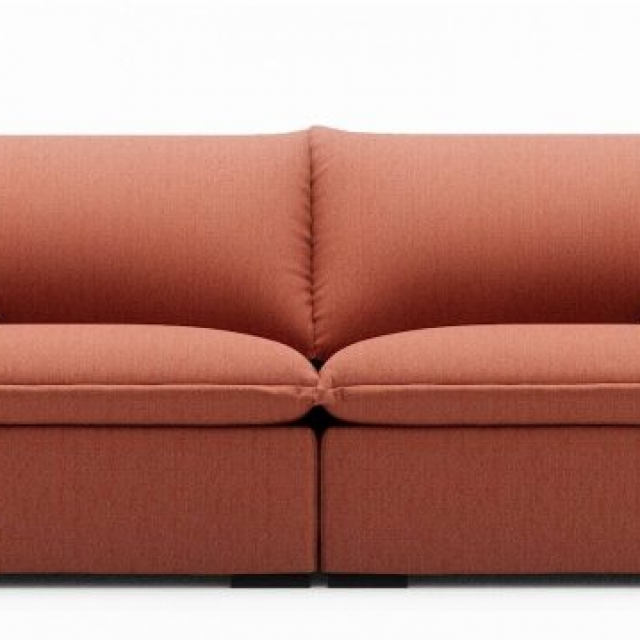

In many cases, a new piece needs to work with several different materials from the same design.

With 3D modeling, the properties and looks of each material can be passed from that single 3D model, properties can be changed almost instantly.

This improves the overall design and development process and reduces production problems. Less costly for manufacturers, and improved products for consumers.

With apps such as the Augmented Reality App from Ikea, those 3D models,

Which are exact replicas of the actual production furniture, can be used to ‘see’ the piece inside the home.

Or simply were not quite what the buyer thought.

3D modeling is a fantastic option for production, reducing development costs and speeding up iterations. It also allows businesses to test the viability of bolder design or new ideas without the high costs. This streamlined development approach helps the industry as a whole and individual furniture manufacturers to introduce new lines regularly while also reducing overheads.

For consumers, the ability to drop accurate, detailed models of every piece into their own home digitally, and see the results through augmented reality, is a way to revolutionize the purchase process and excite consumers.

.png?width=200&height=51&name=ilustra_logo_high_copy_2%20(1).png)

Comments